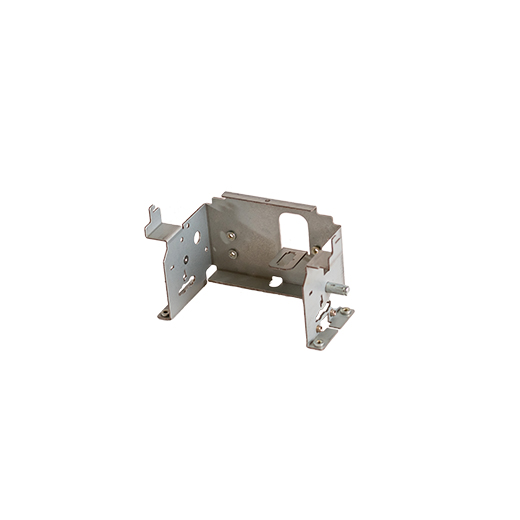

GPSS qualified factories can support orders of all sizes, from short to long run stampings. We also offer Value Added services, including design and secondary operations for your convenience. Our tooling costs are very competitive, which allows us to offer significant savings to our customers.

OUR HIGH-QUALITY METAL PARTS ARE USED IN MANY INDUSTRIES, INCLUDING:

- Automotive

- Telecommunications

- Computer

- Defense

- Office Equipment

- Medical

METAL STAMPING CAPABILITIES AND SERVICES

- Press Capacity to 400 tons

- Single punch to complex progressive dies

- Multi-slide and four-slide, deep draw, lead frame and bus bar capabilities

- In-die tapping and inserts

- Complete tool design and build

- Assembly, and finishing

- MIG, TIG, Spot, Robotic welding

SECONDARY SERVICES

Often stamping will need secondary services such as:

- Machining

- Drilling

- Tapping

- Epoxy and polyester powder coat, plastic dip, e-coat

- Anodizing, Zinc, Nickel, Chrome, HDG

- Welding

- Riveting

- Silk Screening

- Product Assembly

METAL STAMPING AND METAL FORMING MATERIALS

- Aluminum

- Beryllium Copper

- Brass

- Steel

- Pre-coated materials (SECC)

- Stainless steel