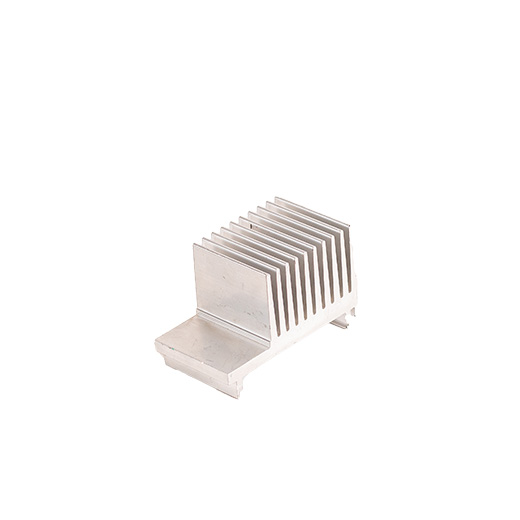

From high-volume conventional parts to close-tolerance, complex components, we produce a wide variety of extrusions. GPSS supplies high-quality, low-cost aluminum and plastic parts and is used by leading OEMs in these fields:

- Automotive

- Telecommunications

- Computer

- Medical

- Defense

- Point of Sale Industries

THE EXTRUSION ADVANTAGE

Extrusion is the process of pushing or drawing a heated billet through a die of the desired cross-section. There are two main advantages of this process over other manufacturing processes: First, the ability to create very complex cross-sections using inexpensive tooling. Second, after you extrude the part, it will have a naturally smooth surface finish.

EXTRUSION MATERIALS

- Copper

- Brass

- Aluminum

- Plastic polymers

- Rubber

- EDPM

- Silicone

- Neoprene

EXTRUSION CAPABILITIES AND SERVICES

- Wide variety of shapes: from pipes and seamless tubing, to custom designs

- Design Assistance

- Cut-to-length Capabilities

- Anodizing

- Fabrication to your print

- Powder coating

- Chromate

EXTRUSION AND SECONDARY OPERATIONS

Aluminum extrusions often need secondary operations to meet the required finish or use. GPSS offers these services through its own affilated factories, Asian Partners, as well as other tariff exempt countries, with great savings over most American Vendors. If your part requires such services as CNC Machining, Plating, Polishing, Anodizing, Coating, or Painting – we have the factories to do it. Our world-class Quality Assurance Staff is there to inspect and monitor operations to ensure your parts are made to your satisfaction.